The coating materials of coated titanium anode plate usually include the following types:

- Platinum group metal oxides: This constitutes a common main component, such as ruthenium oxide (RuO₂), iridium oxide (IrO₂), and others. Among them, ruthenium oxide exhibits excellent chlorine evolution performance in environments with a high chloride ion content, like the seawater medium; iridium oxide demonstrates good electrocatalytic activity and corrosion resistance in oxygen evolution environments and is frequently utilized in environments with low or no chloride ion content, such as soil or fresh water medium, and reinforced concrete medium, etc.

- Iridium tantalum oxides: The iridium tantalum coating also presents satisfactory performance.

- Ruthenium iridium platinum: Some coatings may incorporate combinations of ruthenium iridium platinum.

These precious metal oxide coatings possess the advantages of low resistivity, favorable conductivity, stable chemical composition, and crystal structure, etc. They can enhance the electrocatalytic performance of coated titanium anode plate, reduce the overpotential of oxygen evolution or chlorine evolution reactions, improve corrosion resistance, and prolong service life. In practical applications, the selection of which coating material typically depends on the specific usage environment and electrolysis requirements.

Different coating materials have their respective advantages in different electrolyte systems and industrial applications. For instance, in fields such as the chlor-alkali industry, it is necessary to select the appropriate coating in accordance with the production process and medium conditions to ensure the efficient and stable operation and long service life of the anode. In some special application scenarios, other coating materials with specific compositions might also be developed and employed to meet higher performance requirements.

Titanium anode plate have the following significant functions:

- In the electrolysis industry, such as the production of chlorine gas and caustic soda in the chlor-alkali industry, titanium anode plate can carry out electrolysis reactions efficiently, enhancing production efficiency.

- In the electroplating field, they contribute to obtaining uniform and high-quality coatings, improving electroplating effects.

- In wastewater treatment, through electrochemical oxidation, they promote the decomposition of organic pollutants to achieve the purpose of purifying wastewater.

- They play a crucial role in the process of metal extraction and refining, increasing the purity and extraction rate of metals.

- In the cathodic protection system, they serve as auxiliary anodes to prevent metal structures from being corroded.

titanium anode plate have indispensable and important roles in multiple industrial fields, providing strong support for the optimization and improvement of related processes.

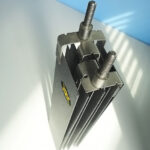

TITANIUM ANODE Manufacture

Some precautions for the use of titanium anode plate

- Avoid mechanical damage: During handling, installation and use, operate carefully to prevent the titanium anode plate from mechanical damage such as collision and scratching, so as not to affect its performance and service life.

- Control current density: According to the specifications and performance of the titanium anode plate, the current density should be controlled reasonably to avoid excessive current causing excessive polarization and damage of the anode plate.

- Prevent chemical corrosion: Avoid the titanium anode plate from contacting substances with strong corrosivity such as strong acids and strong alkalis. When used in a specific electrolyte, ensure that the composition and concentration of the electrolyte are within the tolerance range of the anode plate.

Keep the surface clean: Regularly clean the dirt, sediments, etc. on the surface of the titanium anode plate to maintain good conductive performance and electrocatalytic activity. - Temperature control: Pay attention to the temperature of the operating environment. Too high or too low temperature may affect the performance and stability of the titanium anode plate.

- Firm installation: Ensure that the titanium anode plate is firmly installed in the equipment to avoid poor contact or local overheating due to looseness.

- Regular inspection and maintenance: Regularly inspect the titanium anode plate and promptly detect and handle possible problems such as coating shedding and corrosion.

- Follow operating procedures: Use the titanium anode plate strictly in accordance with relevant operating procedures and safety regulations to ensure the safety and stability of the production process.

correct use and maintenance of titanium anode plates can give full play to their performance, extend service life, and improve production efficiency and quality.