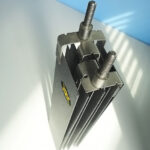

Titanium Jigs for electroplating

In the electroplating production, the titanium jigs for electroplating mainly functions as a conductive, supporting and fixing part, and the titanium jigs for electroplating is connected with the electrode, so that the current is more uniformly transmitted to the part for electroplating.

Full Description

The plated titanium jigs for electroplating should have sufficient mechanical strength and good electrical conductivity; and it requires light weight, small area, sturdy and durable, convenient loading and unloading parts, and proper loading.

Depending on the shape of the part, the technical requirements of the coating, the plating process and the size of the device, different types of jigs for electroplatings are available. For example, there is a difference between an automatic line and a manual line.

In general, the electroplating shop is equipped with a universal titanium jigs for electroplating for various common parts and a special jigs for electroplating designed for only one part. Universal titanium jigs for electroplatings come in many different forms and are suitable for a wide range of processes and parts. Special titanium jigs for electroplatings are divided into two types: one is a special titanium jigs for electroplating designed for large-volume parts production; the other is a special jigs for electroplating designed according to the complex geometry of the part and special process requirements.