Sintered titanium filter disc

The porous titanium plateis a material with excellent filtering performance, usually manufactured by the metal powder rolling method. Powder rolling is a process in which metal powder is directly rolled into metal. First, the metal powder is rolled into a strip on a powder rolling mill, and then sintered, cold-rolled (or hot-rolled), and annealed to make a dense or porous finished strip.

Description

Titanium powder sintered filter plate has good permeability, controlled pore size and pore space, stable shape, high filtration accuracy, wear resistance, good mechanical properties, good thermal conductivity, heat resistance, heat dissipation, high corrosion resistance and can be back washed for multiple uses.

Features

Properties of porous titanium (sintered titanium):

1. Uniform structure, narrow pore size distribution, high separation efficiency.

2. High porosity, low filtration resistance, high penetration efficiency.

3. High temperature resistance, normally can be sued up to 280 degrees.

4. Good chemical stability, acid and alkali corrosion, antioxidant properties.

5. No particle shedding, no secondary pollution to the media, suitable for food hygiene and pharmaceutical GMP requirements.

6. Good mechanical properties, can be used in suction & pressure filtration.

7. Low pressure drop, small footprint, large flow.

8. Good anti-microbial ability.

9. The overall length of up to 1000 mm without welding.

10. Can be online regeneration, easy to be cleaned, long life (several times to typically membrane cartridge)

Sintered titanium filter disc

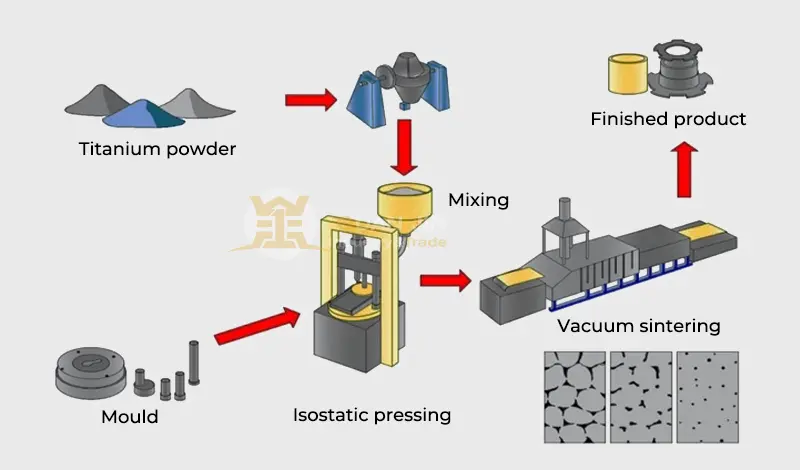

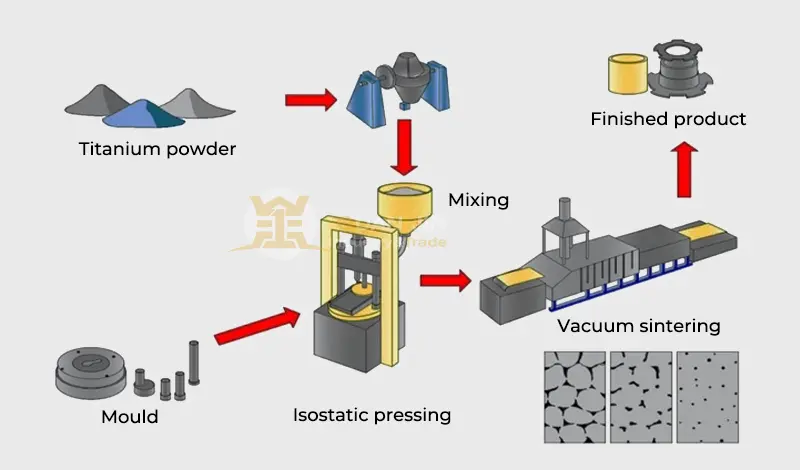

of the Powder Metallurgy Process

Production | Longth(Dia) | Wideth(Dia) | ||

sintered titanium filter discs | Maximum Φ800mm | |||

Sintered porous sheets | Max 800mm | 0.5-30mm |

Filtration precision:

0.45μm─50μm

(0.45 μm, 1 μm, 3 μm, 5 μm, 10 μm, 20 μm, 30 μm, 50 μm)

Pressure: 0.2Mpa/cm2

Temperature resistance: 300 ℃(wet)

Maximum Operating pressure: 0.2Mpa/cm2

Sintered titanium filter discs Applications

Titanium sintered porous materials are mostly used for filtering materials、electrodes、heat transfer materials、catalyst carrier materials、noise cancelling materials according to their physical and structural properties.

1.Decarburization filtration of pharmaceutical liquids.

2.Electrolytic gas industry precision filtration, gas distribution.

3.The medical industry makes biological implants.

4.Water treatment industry odor sterilization filtration and ozone aeration.

5.Clarification and filtration in food and beverage processing.

6.Prefiltration of reverse osmosis system for electronics industry.

7.Terminal filtration of petroleum products in petrochemical industry and filtration of carbonic alkali liquid in chemical industry.

8.High pressure air filtration in aerospace industry.

9.Filtration and recovery of precious metal catalyst in fine chemical industry.

10.The electrode matrix of a fuel cell.