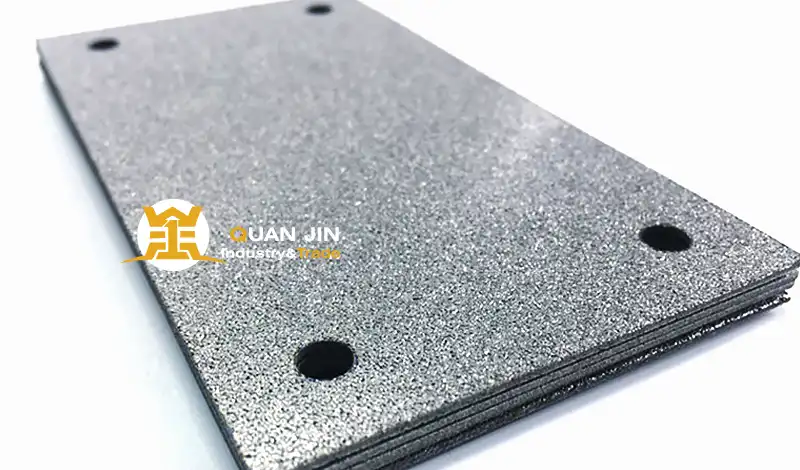

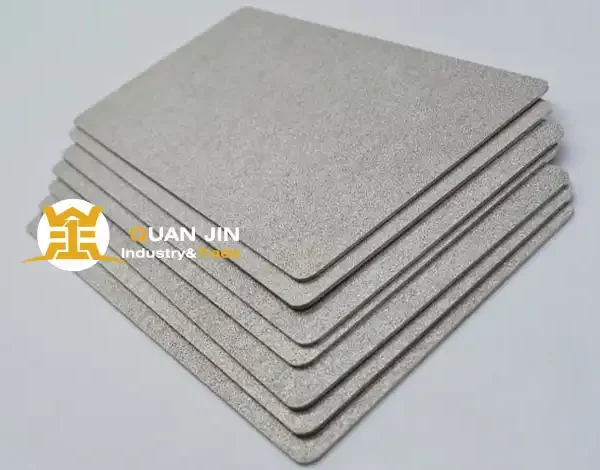

Titanium powder sintered plate

Titanium powder sintered plate, is a porous material with a rigid structure made by forming and high temperature, sintering using titanium as raw material.

Titanium powder sintered plate, contains a large number of connected or semi-connected pores, and the size and distribution of the pores and the porosity can be adjusted according to preparation process to meet the actual needs of customers.

Full Description

Titanium powder sintered filter plate has good permeability, controlled pore size and pore space, stable shape, high filtration accuracy, wear resistance, good mechanical properties, good thermal conductivity, heat resistance, heat dissipation, high corrosion resistance and can be back washed for multiple uses.

Features

- Uniform aperture size, stable aperture space, high separation efficiency

- Good chemical stability, acid and alkali corrosion resistance, anti-oxidation

- Stable morphology, no particle shedding, in line with food hygiene and pharmaceutical GMP requirements

- Good mechanical properties, low differential pressure and high flow rate

- Strong anti-microbial ability, no interaction with microorganisms

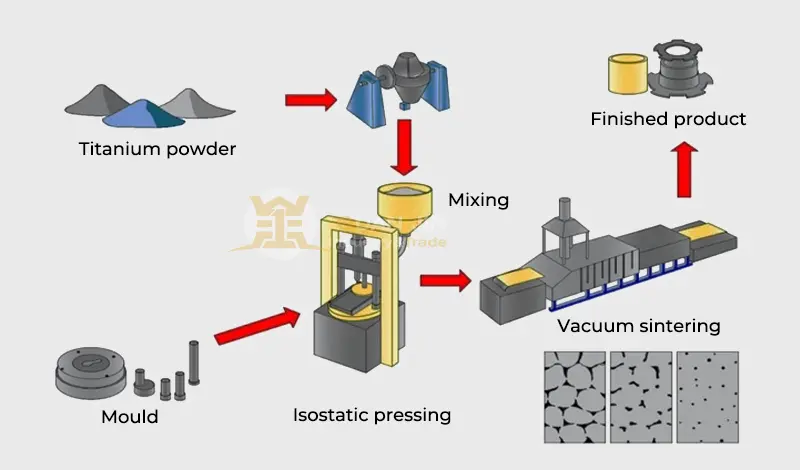

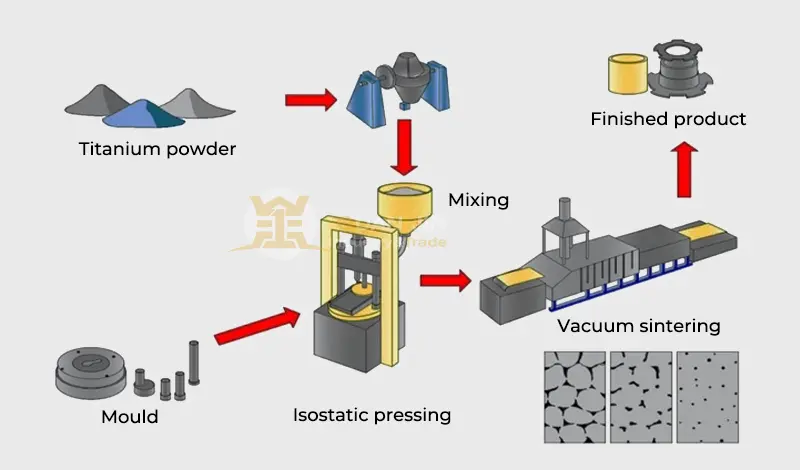

Titanium powder sintered plate

of the Powder Metallurgy Process

Materials | Rating Micron | Porosity | Air Permeability | Working pressure | Heat Resistance |

Titanium powder | 5~80μm | 25~45% | 3-800M²/h | 2.5MPa | 300℃ |

Shape:Round disc、sheet、tube、round bar、cap | |||||

Titanium filter plate uniform pore size, stable pore space, high separation efficiency and high porosity, low filtration resistance and high permeability efficiency. Stable morphological structure, no particle shedding, in line with safety requirements, easy to clean, long service life. Good damping characteristics and impact resistance, can be widely used in industrial and aerospace industry.

Titanium powder sintered Applications

Titanium powder sintered plate materials are used as filtration materials, electrode materials, heat transfer materials, catalyst carrier materials, and noise reduction materials based on their physical and structural properties. Precise filtration and air distribution in electrolysis gas industry, post-sterilization filtration and ozone aeration in water treatment industry, high-pressure air filtration in aerospace industry.

Radioactive particles filtration in the atomic energy industry

It is used in filters to purify liquids and gases by using the characteristics of its uniform aperture size. For example, it is used to purify fuel oil and air in airplanes and automobiles, to filter various liquids and gases in the chemical industry, and to filter radioactive particles in discharged gases in nuclear energy industry.

Anode materials in water electrolyzer

Using its chemical properties, the application in electrochemistry, such as in PEM water electrolysis technology, the anode material in the gas diffusion layer mostly uses titanium powder sintered plate. It has excellent electrical conductivity, catalytic antioxidant properties in PEM water electrolyzer, and can meet PEM water electrolysis long life operation requirements. And it has greater advantages of reducing the cost and improving the performance of PEM water electrolyzer.