Titanium anodes for electrodeposition extraction of non-ferrous metals

Key applications and performance advantages of titanium anode plate materials with noble metal surface modification in the field of electrodeposition extraction of non-ferrous metals.

Overview

Electrodeposition for metal extraction uses insoluble anodes, allowing the metal ions to be extracted in the electrolyte that has undergone leaching and purification treatment to be reduced at the cathode, producing pure metal. Electrolytic metallurgy already accounts for a large proportion in the hydrometallurgical industry.

Principles of Electrolytic Metallurgy

Electrolytic metallurgy is a process of reducing metal ions from a solution to metals using electrical energy and occupies an important position in hydrometallurgy.

Types of metals applied

Non-ferrous metals produced by electrolytic metallurgy include Zn、Cd、Cu、Mn、Co、Cr.

Anode Material Challenges

The greatest difficulty in electrodepositing and extracting metals is to select a suitable anode material. The anode is required to be stable, corrosion-resistant, and capable of long-term use. It should also have good electrocatalytic activity for the anodic process to reduce the overpotential of the anodic reaction and the cell voltage.

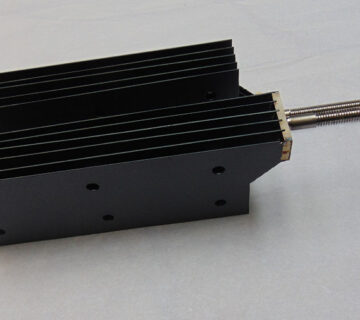

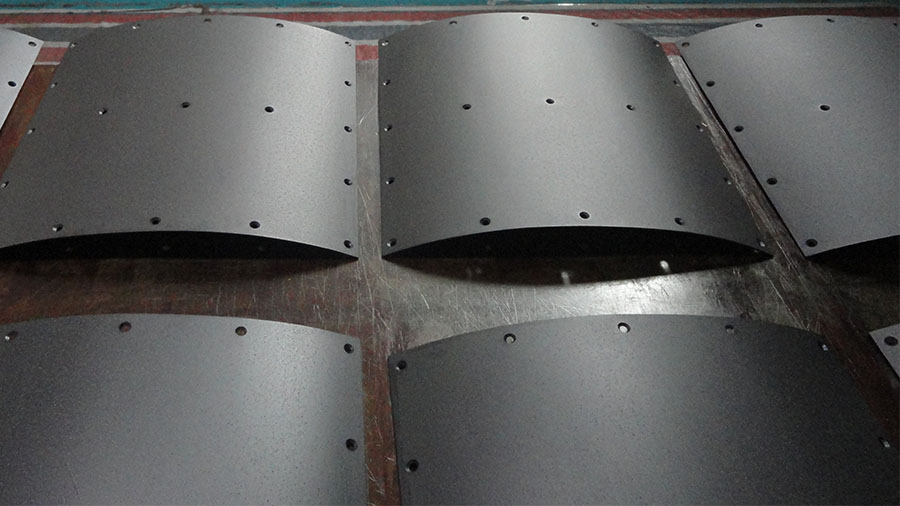

In recent years, coated titanium electrodes have been widely used in the electrodeposition and metal extraction industry. As hydrometallurgy technology becomes the mainstream technology, titanium anode plate materials with noble metal surface modification are bound to become the key materials in this field.

Titanium anodes for electrodeposition extraction of non-ferrous metals

Electrowinning of metals from chloride solutions

In the electrowinning of metals from chloride solutions, the factory used graphite anodes in the past. Graphite materials have high resistance, resulting in high power consumption. The graphite anodes have low strength, are prone to wear and tear, and have a short working life. Graphite contaminates the cathode products, making it difficult to obtain high-purity metals.

Anodic reaction characteristics

When electrolyzing a chloride solution, the main reaction at the anode is chlorine evolution. Chlorine gas is evolved at the anode. The most important characteristics of the active coating are low chlorine overpotential, good electrical conductivity, strong chlorine corrosion resistance, and a long anode service life.

The use of precious metal surface - modified titanium anode plate materials can increase the anodic oxidation potential, which is beneficial to extending the working life of the anode.

Case: Electrowinning of Co from Cobalt Chloride Solution

- Graphite anodes can only be used for a few months, while the noble metal surface-modified titanium anode plate material has a working life of up to 3 years.

- The voltage of the graphite anode cell is 4.1V, while that of the coated titanium anode is 3.7V, a reduction of 0.4V.

- The current efficiency is increased from 90% to 94%.

- Producing 1t of Co saves 400kW•h of electric energy, that is, it saves 10% of electricity.

- It can reduce the carbon content in Co and improve the metal grade.

Case: Electrowinning of Silver from Silver Chloride Solution

At 250 A/m², the chlorine overpotential of the coated titanium electrode is 0.1979 V. The overpotential value is very small, indicating that the electrocatalytic activity of the titanium electrode is greatly improved after the surface modification of the noble metal.

Electrowinning extraction of metals from sulfate solutions

In the electrowinning of metals from sulfate solutions, lead-based alloy electrodes are generally used. However, during the electrolytic production process, the lead anode will dissolve, which not only consumes the anode material but also affects the working life of the anode. Moreover, the lead dissolved in the solution will precipitate on the cathode, increasing the lead impurity content in the metal and reducing the product quality.

Anodic reaction characteristics

When electrodepositing metals from sulfate solutions, oxygen is mainly generated at the anode. The most important characteristics of the active coating are high electrocatalytic activity for oxygen, good electrical conductivity, good durability against oxygen, and a long anode working life.

Case: Electrowinning of nickel from nickel sulfate solution

Performance comparison of lead-silver anodes and surface-modified titanium anode plates for precious metals:

- The exchange current density value of the lead-silver anode is 17.09 × 10⁻⁷ A/cm²

- The material of the precious metal surface - modified titanium anode plate is 3.85 × 10⁻⁵ A/cm²

- The larger the exchange current value, the smaller the required overpotential, the higher the reaction rate, indicating that the electrode has higher electrocatalytic activity.

Summary of performance advantages

Electrowinning of metals from a mixed solution of chloride and sulfate

When electrolyzing in a chloride - sulfate mixed system, chlorine and oxygen are simultaneously evolved at the anode. This causes extremely severe corrosion to the anode material. Compared with a single - salt system, the anode operates under more harsh conditions, thus putting forward higher requirements for the anode material.

Advantages of titanium anodes

The titanium anode plate material with precious metal surface modification is beneficial to inhibit the oxygen evolution reaction. It is suitable for use in the electrowinning of metals in a mixed solution of chloride and sulfate. Its working life reaches 3 to 8 months, which is far superior to other anode materials.

High corrosion resistance

Effectively resist the highly corrosive environment of the mixed solution.

Long service life

The working life can reach 3 to 8 months, far exceeding that of traditional anodes.

Efficient electrocatalysis

Suppress the oxygen evolution reaction and improve the electrocatalytic efficiency.

Summary of the advantages of titanium anodes

Low overpotential

Significantly reduce the anode reaction overpotential and decrease the power consumption.

long lifespan

The working life is significantly longer than that of traditional anode materials, reducing the replacement frequency.

High corrosion resistance

Remain stable in various electrolytes and have strong corrosion resistance.

High catalytic activity

Improve the electrode reaction rate and enhance production efficiency.

The product has a high purity.

Reduce impurity contamination and improve the purity of metal products.

Environmental protection and energy conservation

Reduce energy consumption and waste generation, which is in line with the concept of green production.