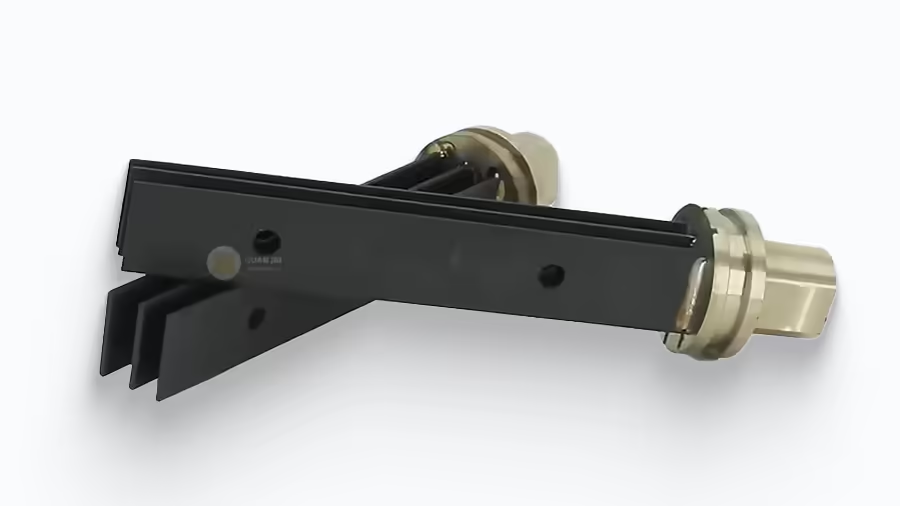

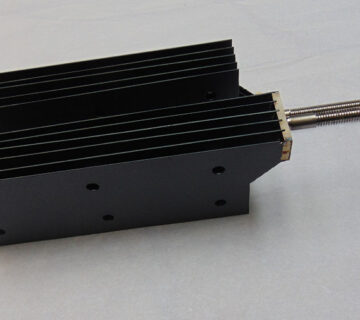

Titanium anode for electrolyzed water

Titanium anode for water electrolysis, namely titanium-based metal oxide coated electrodes (MMO), titanium has excellent physical and chemical properties such as low density, high strength, and strong corrosion resistance, and can maintain stable structure and performance in harsh electrolytic environments. Coating the surface of the titanium substrate with metal oxide coatings with high catalytic activity, such as IrO₂, RuO₂, etc., endows the titanium anode with good electrocatalytic performance, which can significantly reduce the overpotential of oxygen evolution reaction (OER) and improve the efficiency of water electrolysis. In addition, titanium anodes have good dimensional stability, with small changes in polar distance during long-term electrolysis, which can ensure that the electrolysis operation is carried out under a stable cell voltage, thereby effectively reducing energy consumption.

The stability of titanium anode used in water electrolysis within the electrolysis system is of non-negligible significance. Their excellent corrosion resistance and stable electrocatalytic performance can reduce the occurrence of electrode failures, extend the service life of electrolyzers, and provide reliable guarantees for the industrial production of water electrolysis.

Working Principle of Titanium Anodes for Water Electrolysis

- Anodic oxidation reaction and catalytic principle

During the process of water electrolysis, the oxygen evolution reaction (OER) occurring at the titanium anode is a crucial step. In an alkaline medium, hydroxide ions (OH⁻) on the anode surface participate in the reaction, with the specific reaction formula being: 4OH⁻ – 4e⁻ → O₂↑ + 2H₂O. In this process, hydroxide ions lose electrons and are oxidized to form oxygen and water. In an acidic medium, however, the reaction is based on the oxidation of water molecules, with the reaction formula: 2H₂O – 4e⁻ → O₂↑ + 4H⁺. Water molecules lose electrons on the anode surface, generating oxygen and hydrogen ions.

The precious metal oxide coatings (such as IrO₂) on the surface of titanium anodes play a crucial catalytic role in this reaction. From a microscopic perspective, the IrO₂ coating has a unique crystal structure and electronic properties, with a large number of active sites on its surface. These active sites can interact strongly with reactants (OH⁻ or H₂O), change the reaction path, reduce the activation energy of the reaction, and thus enable the oxygen evolution reaction to proceed at a lower overpotential. - Synergistic effect between titanium substrate and coating

A titanium anode is a composite structure consisting of a titanium substrate and a surface coating. There is a close synergistic effect between the two, which together determine the performance of the electrode.Commercially pure titanium (Gr1/Gr2) is often used as a base material. Commercially pure titanium has good chemical stability and mechanical properties. In most chemical environments, a dense oxide film (TiO₂) is quickly formed on the titanium surface. This oxide film has excellent chemical stability and can effectively prevent further chemical reactions between the substrate and the electrolyte, thereby protecting the substrate from corrosion. In strongly acidic sulfuric acid solutions or strongly alkaline KOH solutions, this oxide film can exist stably, allowing the titanium substrate to maintain structural integrity even in these extreme environments.On the surface of a titanium substrate, the preparation of nanoscale catalytic coatings using the thermal decomposition process involves applying a solution containing metal salts onto the titanium substrate surface, followed by decomposition at high temperatures to convert the metal salts into a metal oxide coating. This method can precisely control the composition and thickness of the coating, resulting in uniform, dense nanoscale coatings.

A composite structure of “substrate + high-activity coating” is formed between the titanium substrate and the coating. This enables the coating to fully exert its catalytic effect. Moreover, the high electrical conductivity of the coating ensures the uniform distribution of current on the coating surface, avoiding electrode damage caused by local current concentration.

Performance advantages of titanium anodes for electrolyzed water

By optimizing the coating design, such as using a gradient coating design (e.g., IrO₂-RuO₂ composite coating), the catalytic activity of titanium anodes can be further improved and energy consumption can be reduced. IrO₂ has good oxygen evolution catalytic activity and can reduce the overpotential of the oxygen evolution reaction; RuO₂ has high electrical conductivity and stability. When compounded with IrO₂, it can form complementary advantages. In such a composite coating, coatings of different compositions play a role in different reaction stages, reducing the activation energy of the oxygen evolution reaction by 10% – 20%.

Titanium anodes, with their excellent performance in water electrolysis technology, have become a key material driving the development of green energy. Their unique corrosion resistance, high catalytic activity, and excellent structural stability enable them to show great application potential in fields such as industrial water electrolysis for hydrogen production, water treatment, and environmental governance, providing effective technical means to solve energy and environmental problems.

In terms of working principles, during the process of electrolyzing water, titanium anodes significantly reduce the overpotential of the oxygen evolution reaction through the catalytic effect of their surface coatings, thereby improving electrolysis efficiency. The synergistic effect between the titanium substrate and the coating ensures the stable operation of the electrode under complex working conditions, enabling efficient electrical energy conversion. In terms of preparation processes, by continuously optimizing the coating material system and innovating preparation technologies—such as developing noble metal-based coating technologies, exploring non-noble metal coatings, adopting gradient structure designs, and enhancing interface bonding—the performance of titanium anodes has been further improved, laying a solid foundation for their wide application.