The Definition and Structure of

Titanium Anodes

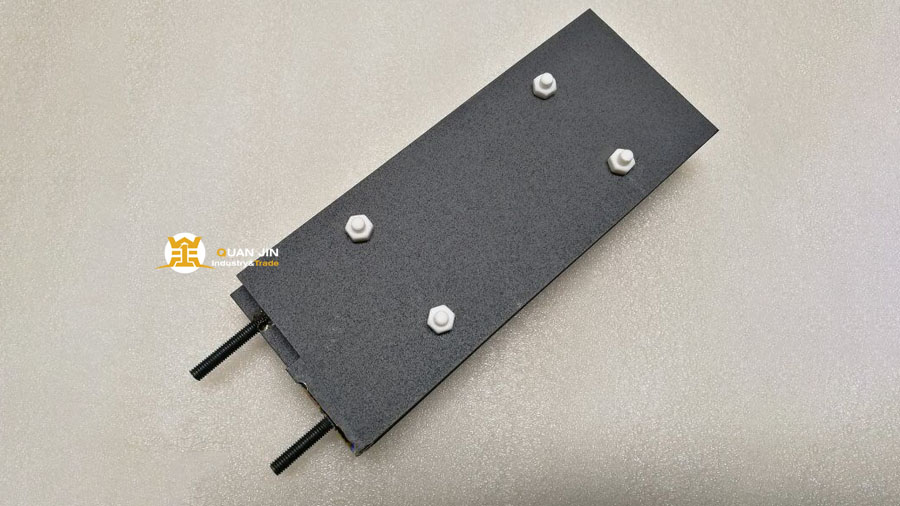

Titanium anode, whose full name is titanium-based metal oxide coated electrode (MMO), also known as dimensionally stable anode (DSA), is an insoluble anode that plays a crucial role in electrochemical processes. It is an electrode material composed of a titanium substrate with a layer of electrocatalytically active metal oxide coating applied to its surface through a specific process. This unique structural design endows the titanium anode with excellent properties, enabling the mixed metal oxide coated titanium anode to be widely used in the electrochemical field.

The titanium substrate is the supporting framework of the titanium anode, and industrial pure titanium materials such as TA1 and TA2 are usually selected. Titanium materials have the characteristics of low density, high strength, resistance to high temperatures, good processing performance, and excellent corrosion resistance. In various harsh electrochemical environments, the titanium substrate can maintain a stable physical shape and mechanical properties, providing a solid and reliable support for the surface coating. It ensures that the entire electrode will not be deformed or damaged during the long-term electrolysis process, and guarantees the long-term stable operation of the electrode.

The metal oxide coating is the core functional part of the titanium anode. It is coated on the surface of the titanium substrate with precious metal oxides (such as platinum, ruthenium, iridium, etc.) and non-precious metal oxides in a certain proportion and process. These oxides have the characteristics of stable chemical composition and a dense crystal structure, endowing the titanium anode with good electrical conductivity and excellent electrocatalytic performance. The existence of the coating not only makes up for the insufficient electrical conductivity of titanium itself, but also can significantly reduce the overpotential of electrode reactions such as oxygen evolution and chlorine evolution. In the chloride electrolyte system, the titanium anode with a ruthenium-based oxide coating can effectively reduce the overpotential of chlorine evolution, enabling the electrolysis process to proceed smoothly at a relatively low voltage, thus saving a large amount of electrical energy and improving the electrolysis efficiency. The chemical composition and microstructure of the coating can be precisely regulated according to different application requirements to achieve efficient catalysis of specific electrode reactions. In situations where high oxygen evolution activity is required, a mixed metal oxide coating mainly composed of iridium dioxide can be used, and the proportion and distribution of various elements in the coating can be optimized to enhance the catalytic ability of the electrode for the oxygen evolution reaction.

In the modern industrial system, the electrochemical industry holds a pivotal position. It has a wide range of application fields, covering several key industries such as the chlor-alkali industry, electroplating, electrolytic metallurgy, wastewater treatment, and new energy development. As the core component of the electrochemical process, the performance of electrode materials is directly related to the production efficiency, product quality, and cost control of the entire electrochemical industry. Among numerous electrode materials, titanium anodes have become a crucial factor in promoting the development of the electrochemical industry due to their unique physical and chemical properties and excellent electrochemical performance.

Titanium anodes generally refer to electrode materials with titanium as the substrate and a surface coated with a layer of metal oxide coating that has specific catalytic activity and corrosion resistance. Titanium metal itself has advantages such as low density, high strength, resistance to high temperatures, and outstanding corrosion resistance. These characteristics enable titanium anodes to maintain stable performance in various harsh electrochemical environments. The presence of the surface coating further endows titanium anodes with good electrical conductivity, high catalytic activity, and a relatively low overpotential for oxygen or chlorine evolution, thus significantly improving the efficiency of the electrode reaction.

With the increasing global emphasis on environmental protection, the field of wastewater treatment has become a new hotspot for the application of electrochemical technologies. Titanium anodes perform excellently in wastewater treatment technologies such as electrocatalytic oxidation and electro-Fenton. Under the action of an electric field, it can generate highly oxidizing free radicals, such as hydroxyl radicals (・OH). These free radicals can rapidly decompose the organic pollutants in wastewater, mineralizing them into carbon dioxide and water, thus achieving the harmless treatment of wastewater. Studies have shown that the electrocatalytic oxidation technology using titanium anodes can achieve a COD removal rate of over 80% for wastewater containing refractory organic pollutants, such as printing and dyeing wastewater and pharmaceutical wastewater. This significantly improves the biodegradability of the wastewater, creating favorable conditions for subsequent biological treatment.

In the field of new energy, with the continuous growth of the demand for clean energy, the technology of hydrogen production by water electrolysis, as a sustainable hydrogen production method, has received widespread attention. Titanium anodes exhibit high oxygen evolution activity and stability during the water electrolysis process, which can effectively reduce the electrolysis voltage and improve the hydrogen production efficiency. In addition, in the research and development of new types of batteries, such as vanadium redox flow batteries and zinc-air batteries, titanium anodes also serve as key electrode materials, making important contributions to improving the energy density, cycle life, and charge-discharge efficiency of the batteries.

In the electroplating industry, titanium anodes also play an irreplaceable role. During the electroplating process, the anode needs to have good electrical conductivity and stability to ensure that metal ions can be uniformly deposited on the surface of the plated parts. Titanium anodes can not only meet these requirements, but also achieve precise control of the electroplating process by optimizing the composition and structure of the coating, thus obtaining high-quality, uniform and dense coatings. For example, in the chromium plating process, the use of titanium anodes can effectively reduce the generation of chromium mist and lower environmental pollution. At the same time, it can improve the hardness, wear resistance and corrosion resistance of the chromium plating layer, enhancing the market competitiveness of the products.

The Electrochemical Reaction Process of Titanium Anodes

In different electrochemical industrial applications, the working principles and electrochemical reaction processes of titanium anodes have both commonalities and certain differences. Taking two typical fields, namely the chlor-alkali industry and the production of electrolytic copper foil, as examples can help us understand the working mechanism of titanium anodes more clearly.

In the chlor-alkali industry, the electrolysis of saturated brine is its core process. As an insoluble anode, the titanium anode plays a crucial role in this process. When direct current passes through the electrolytic cell, an oxidation reaction occurs on the surface of the titanium anode. Chloride ions lose electrons at the anode and are oxidized to chlorine gas, which escapes in the form of gas. At the cathode, a reduction reaction takes place. Water molecules gain electrons at the cathode, generating hydrogen gas and hydroxide ions. As the electrolysis continues, chlorine gas is produced in the anode chamber, and hydrogen gas and sodium hydroxide solution are produced in the cathode chamber, thus achieving the production of the main products in the chlor-alkali industry.

The reason why the titanium anode can efficiently promote this process is that its surface coating has good electrocatalytic activity for the chlorine evolution reaction, which can reduce the overpotential of the reaction, enabling the electrochemical reaction to proceed smoothly at a relatively low voltage. This improves the electrolysis efficiency and reduces the energy consumption. At the same time, the high corrosion resistance of the titanium substrate ensures that the electrode can operate stably for a long time in the strongly corrosive brine environment, extending the service life of the electrode and reducing the equipment maintenance cost.

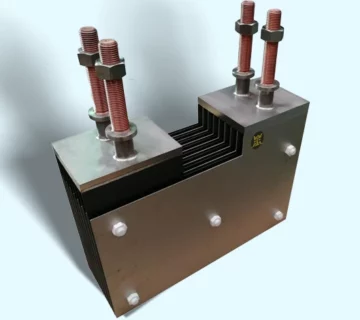

In the production of electrolytic copper foil, the titanium anode also plays an important role. The production of electrolytic copper foil usually takes place in a copper sulfate electrolyte system. During the electrolysis process, the titanium anode, as the positive pole of the current, provides electrons for the entire electrochemical reaction. The main electrochemical reaction occurring on the anode surface is the oxidation reaction of water, that is, water molecules lose electrons at the anode to generate oxygen gas and hydrogen ions. At the cathode, copper ions gain electrons and are reduced to metallic copper, which is deposited on the surface of the cathode to form copper foil. In this process, the good electrical conductivity of the titanium anode can stably transfer the current to the electrolyte, ensuring the smooth progress of the electrolysis reaction. Meanwhile, the corrosion resistance of the titanium anode makes it less likely to be corroded in the strongly acidic electrolyte containing copper ions and sulfuric acid, enabling it to work stably for a long time and thus ensuring the stable operation of the electrolytic copper foil production line. In addition, by optimizing the coating structure and composition of the titanium anode, its catalytic activity for the oxygen evolution reaction can be further improved, the cell voltage can be reduced, the electrolysis efficiency can be increased, and at the same time, the energy consumption and production cost can be reduced.

Classification of Titanium Anodes

The classification of titanium anodes is mainly based on the functions of their surface catalytic coatings. Different coatings determine the specific roles and application fields of titanium anodes in electrochemical reactions. Common types of titanium anodes include chlorine evolution anodes and oxygen evolution anodes.

Chlorine evolution anodes are mainly applied in chloride electrolyte systems, such as in the electrolysis of saturated brine in the chlor-alkali industry and the electrolysis of seawater. Their surfaces are usually coated with ruthenium-based oxide coatings, such as Ru-Ir-Ti anodes, Ru-Ir-Sn-Ti anodes, etc. In a chloride electrolyte, chloride ions undergo an oxidation reaction on the anode surface to form chlorine gas. The key role of the chlorine evolution anode is to reduce the overpotential of this reaction, enabling chlorine gas to be released smoothly at a relatively low voltage. Taking the chlor-alkali industry as an example, during the electrolysis of saturated brine, the presence of the chlorine evolution anode makes this reaction proceed efficiently. The ruthenium-based coating has good electrocatalytic activity, which can effectively promote the oxidation of chloride ions and improve the efficiency of chlorine evolution. For a chlorine evolution anode with a ruthenium-based coating, the overpotential for chlorine evolution is reduced by approximately 100 – 150mV compared to the traditional graphite anode, greatly improving the electrolysis efficiency and reducing energy consumption. In addition, this type of anode has excellent corrosion resistance in chloride solutions and can maintain stable performance during a long-term electrolysis process, ensuring the continuity and stability of chlor-alkali production.

Oxygen evolution anodes are mainly used in sulfate electrolyte systems and play an important role in electroplating, hydrogen production by water electrolysis, and some wastewater treatment processes. Their coatings are usually mainly composed of iridium-based oxides, such as Ir-Ta anodes, Ir-Ta-Sn anodes, high-iridium anodes, etc. In these electrolytes, water or other oxygen-containing ions undergo an oxidation reaction on the anode surface to form oxygen. The main function of the oxygen evolution anode is to efficiently catalyze this oxygen evolution process. An oxygen evolution anode with an iridium-based coating can significantly reduce the overpotential for oxygen evolution and improve the efficiency of water electrolysis. Experimental data shows that for a water electrolysis device using an oxygen evolution anode with an iridium-based coating, under the same conditions, the overpotential for oxygen evolution is reduced by 0.2 – 0.3V compared to a common electrode, greatly improving the hydrogen production efficiency and reducing energy consumption. At the same time, the oxygen evolution anode has good stability in acidic and highly oxidizing electrolytes and can adapt to complex electrochemical environments, ensuring the smooth progress of electrochemical reactions.

In addition to the above two main types, there are also some titanium anodes for special purposes. The platinum-plated anode (platinum titanium mesh/platinum titanium plate) uses titanium as the base material and has a precious metal platinum plated on its surface, with a coating thickness generally of 1~5μm. The platinum-plated anode has extremely high chemical stability and catalytic activity and is often used in fields with extremely high requirements for electrode performance, such as precision electroplating and the manufacturing of electronic devices. It can ensure the provision of a stable current and efficient electrocatalytic effect in complex electrochemical environments, thus obtaining a high-quality coating or achieving a high-precision electrochemical reaction.

Advantages of Titanium Anodes in the Electrochemical Industry