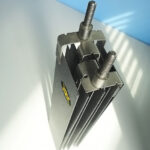

Electrolytic copper foil titanium anode

Copper foil titanium anode is an important component in the electrolytic cell, providing a carrier for electron transfer and catalytic oxidation in the electrolytic copper foil manufacturing process, directly determining the efficiency and quality of electrolytic copper foil, and is widely used in the electrolytic copper foil production field. Our adopts the design idea of multi-layer, gradient, nano coating and plasma treatment process to produce copper foil anodes with high conductivity, long life and low cost.

The stability, catalytic activity and load capacity of copper foil electrolytic titanium anodes depend on:

Multicomponent doping

Multilayer gradient recombination

High uniformity

The copper foil anode is a back-drawn anode plate or embedded anode. Under the action of electric field, the catalytic oxidation reaction occurs on the surface of the copper foil anode and releases the electrons required for the reduction of copper ions, and the catalytic activity and uniformity of the copper foil anode directly affect the performance of the copper foil.

Electrolytic copper foil titanium anode has high catalytic performance, good stability and low load.Electrolytic copper foil industry uses arc structure electrolytic cell, by electrolyzing copper sulfate solution to produce copper foil, in the diameter of 2-3 meters titanium cathode roller plated copper, peel the copper foil at one end of the drum; The distance between the anode and the cathode roll is as small as 5mm, but it is necessary to ensure that the thin copper foil of uniform thickness is deposited on the smooth cathode roll. Due to the strict requirements of product quality and performance, the stability of electrolytic conditions in production is strictly required, and the anode should carry a great current. Precious metal coated titanium electricity has the advantages of light weight, long service life, high current power supply, stable operation, no environmental pollution, etc., and has been widely used in the world. The titanium anode for electrolytic copper foil produced by us has low oxygen evolution potential, oxide grain reaches nanometer level, uniform and stable discharge, and good quality of raw foil.