What are some common coating materials for titanium anodes?

Some common coating materials for titanium anodes include:

- Ruthenium oxide (RuO₂): It provides good electrocatalytic activity.

- Iridium oxide (IrO₂): Known for its stability and catalytic properties.

- Platinum (Pt): Offers high catalytic efficiency but is expensive.

- Lead dioxide: has a high oxygen evolution potential.

Mixed metal oxide coated titanium anode, combined with the advantages of different metals to improve electrochemical performance for the purpose.

The choice of coating material depends on the specific application requirements and operating conditions of the titanium anode.

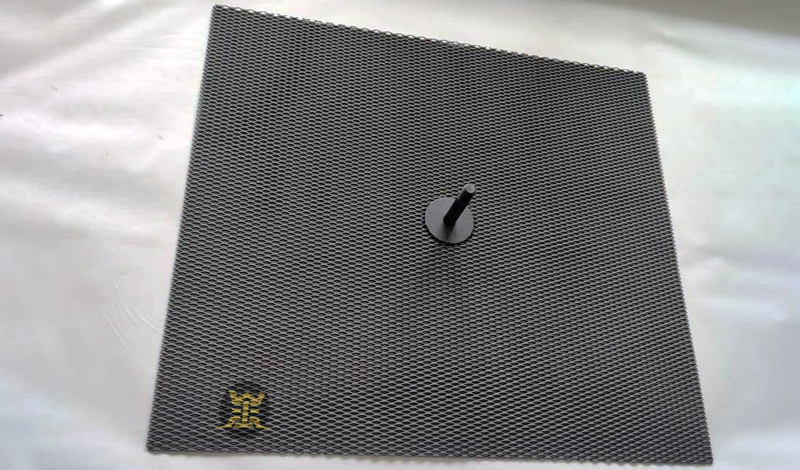

Introduction to coated titanium anode

Coated titanium anode refers to a titanium metal that has a special coating on its surface.

Titanium is a commonly used base material due to its good corrosion resistance and mechanical properties. The coating on the titanium anode is typically designed to enhance its electrochemical performance, such as improving its catalytic activity and stability.

These coated titanium anodes are widely used in electrochemical processes, such as electrolysis, electroplating, and some industrial electrochemical reactions. The coating can vary depending on the specific application requirements and may include substances like precious metals or metal oxides. The coating helps to lower the electrode potential, increase the current efficiency, and prolong the service life of the anode.

What are the advantages of coating titanium anodes?

- The advantages of coated titanium anodes include:

Excellent corrosion resistance: They can withstand harsh chemical environments, reducing the risk of electrode degradation and extending service life. - High catalytic activity: The coating enhances the electrochemical reaction rate, improving the efficiency of processes such as electrolysis and electroplating.

- Low overpotential: This leads to energy savings and lower operating costs.

- Good stability and durability: They maintain performance over an extended period, reducing the need for frequent replacements.

- Versatility: Can be tailored for specific electrochemical applications by adjusting the composition and structure of the coating.

- Resistance to fouling and passivation: Minimizing the negative effects of impurities and deposits on electrode performance.

- Reduced environmental impact: Due to their higher efficiency and longer lifespan, they can contribute to more sustainable processes.

What is the performance of different coating materials in terms of electrocatalytic activity?

The electrocatalytic activity of different coating materials on titanium anodes varies.

Ruthenium oxide (RuO₂) exhibits relatively high electrocatalytic activity, especially in chlorine evolution reactions. However, it may have some stability issues over long-term use.

Iridium oxide (IrO₂) is known for its superior stability and decent electrocatalytic activity. It performs well in oxygen evolution reactions and shows better durability compared to RuO₂.

Platinum (Pt) has extremely high electrocatalytic activity but is prohibitively expensive for large-scale industrial applications.

Mixed metal oxides like Ru-Ir oxides often provide a balance between activity and stability. The combination of ruthenium and iridium in the correct proportions can result in improved overall performance, combining the high activity of ruthenium with the stability of iridium.