MMO anodes for cathodic protection, It adopts titanium as the base material, thus being easy to be processed into various required shapes, and is lightweight and convenient to install. Titanium anodes for impressed current cathodic protection come in various shapes such as strip-shaped and tubular. As the electrode surface is covered with a highly catalytically active oxide layer, the potential of the titanium substrate exposed at some surface defects usually does not exceed 2V. Therefore, the surface passivation film of the titanium substrate will not be broken down and damaged (when used in soil, the applied voltage is generally controlled below 60V). The mixed metal oxide anode also has extremely excellent physical, chemical and electrochemical properties. The resistivity of its coating is 10-7Ω.m, with small polarization and low consumption rate. By adjusting the composition of the oxide layer, it can be made suitable for different environments, such as seawater, fresh water and soil.

The service life of the mixed metal oxide anode in the ground bed can reach 20 years at A working current density of 100A/m ², with a consumption rate of approximately 0.1 mg/ A. Even when the current density reaches 1000A/ m ², the electrode will not show passivation or dissolution phenomena, and its performance is reliable. Under the protection conditions of shallow soil and deep soil containers, the anode used for cathodic protection has a service life of ≥20 years at a current density of 100A/m².

For titanium anodes used in cathodic protection under seawater medium conditions, the service life is ≥20 years at a current density of 600A/m². Due to the advantages that mixed metal oxide titanium anodes have that other anodes do not possess, it has become the most ideal and promising auxiliary anode material at present.

Impressed current cathodic protection is an effective method to prevent corrosion of metal structures in media such as seawater, fresh water and soil. In the impressed current cathodic protection system, the auxiliary anode plays a crucial role, and its performance directly affects the efficiency and reliability of cathodic protection. There are many materials that can be used as auxiliary anodes, such as graphite, high-silicon cast iron, lead-silver alloys, platinum-plated or platinum composite anodes (platinum/titanium, platinum/niobium, platinum/tantalum), and titanium-based metal oxide anodes, etc. Among various auxiliary anodes, titanium-based metal oxide anodes have been increasingly applied in impressed current cathodic protection projects due to their excellent electrochemical activity, low consumption rate, long service life, good environmental adaptability (including seawater, fresh water, soil and other media), and high cost performance. It represents the development and application direction of high-performance auxiliary anode materials.

Titanium based MMO anodes are composed by coating a mixed metal oxide layer with electrocatalytic activity on a titanium substrate. Titanium as the anode substrate not only has good processability. Moreover, it has the characteristics of valve metals. When the titanium substrate is exposed on the anode surface, the anode current will be discharged from the surface with a mixed metal oxide coating, and a passivation film will form on the exposed substrate surface, protecting the substrate. Other valve metals such as niobium and tantalum can also be used as anode substrates. They have higher stability than titanium, but are more expensive and are usually only adopted in situations where titanium is not suitable. Therefore, titanium is widely used as the matrix for platinum composite anodes and mixed metal oxide anodes.

MMO Anodes (Mixed Metal Oxide) for Cathodic Protection

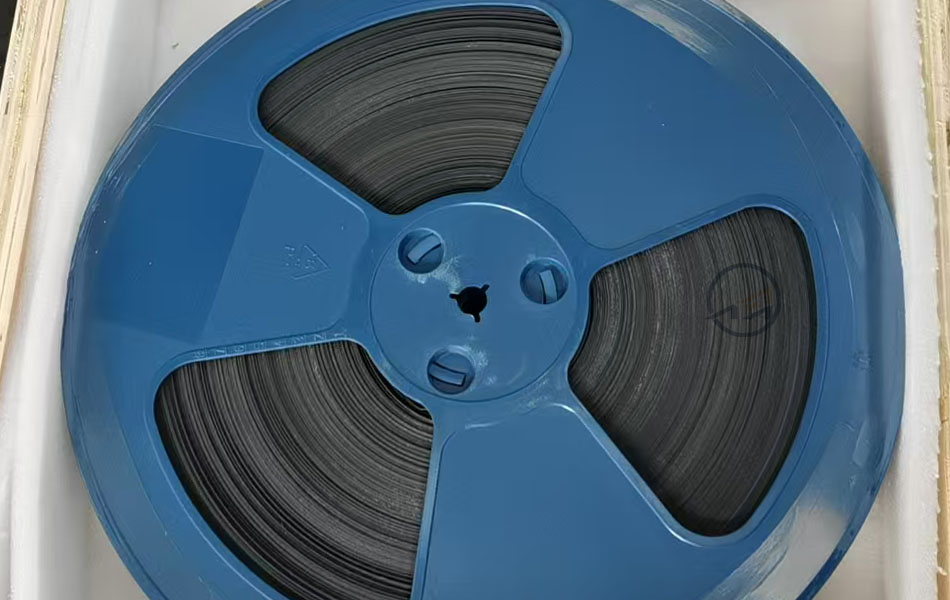

Titanium anode strip

Titanium anode strip At present, it has been used as an auxiliary anode in cathodic protection systems, typically for cathodic protection of ground storage tank bottom plates and reinforced concrete structures. When mixed metal oxide anode strips are used for cathodic protection of the outer wall of storage tank bottom plates with external current, they are generally laid perpendicularly to titanium conductive strips, and the intersection points are spot-welded with a special welding machine to form an anode network. The connection is made with anode-specific connectors.

The mixed metal oxide anode band is composed of a layer of metal oxide with electrocatalytic activity covering a titanium substrate. The oxide coating has small polarization and extremely low consumption rate. By adjusting the composition of the oxide layer, it can be adapted to different environments, such as seawater, fresh water, and soil media. Because the mixed metal oxide anode strip has advantages that other anodes do not possess, it has become the most ideal and promising auxiliary anode material at present.

Common specifications of anode bands:

Mixed metal oxide films: IrO2, Ta2O5

Specification: Width 6.35mm, thickness 0.635mm

Standard length: 152 meters per roll

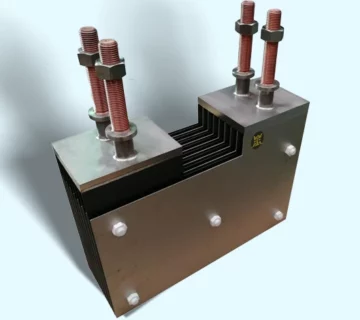

Common specifications of titanium conductive sheets:

The composition of titanium: ASTMB 265 Gr1

Specification: Width 12.7mm, thickness 0.90mm

Standard length: 152 meters per roll