With the rapid development of the global ship transportation industry, it has inevitably led to a sharp increase in the discharge of ballast water. The alien species, pathogenic microorganisms, and chemical pollutants carried in ballast water pose a serious threat to the balance of marine ecosystems. In response, the International Maritime Organization (IMO) has formulated the strict International Convention for the Control and Management of Ships’ Ballast Water and Sediments, requiring the global merchant fleet to be equipped with efficient ballast water treatment systems. Against this background, the electrolysis method has gradually become a research hotspot in the field of ballast water treatment due to its advantages such as no need for adding chemical agents, high treatment efficiency, and environmental friendliness. This technology generates strong oxidizing substances (such as hypochlorous acid, hydroxyl radicals, etc.) through the electrolysis of seawater to inactivate organisms in ballast water. The performance of its core component, the titanium anode, directly determines the stability and economy of the treatment system.

Titanium electrodes serve as active carriers for electrolytic reactions,Its structural design and surface coating technology are the keys to improving electrolysis efficiency. Studies have shown that by regulating the composition and microstructure of the surface coating on the titanium substrate, the chlorine evolution overpotential and corrosion resistance of the electrode can be significantly optimized.

Innovations in ballast water treatment technology are closely related to marine ecological protection. The improvement of titanium electrode performance can not only reduce the operating cost of the electrolysis method but also achieve the goal of green treatment by reducing secondary pollution. With the continuous improvement of nanocoating technology, composite material design, and service life prediction models, the stability of titanium electrodes under harsh conditions such as high pressure and high salinity will be further enhanced, thereby promoting electrolysis to become the mainstream technical solution for ship ballast water treatment.

Principle of Ballast Water Treatment by Electrolysis

- Electrolytic ballast water treatment technology achieves the inactivation of microorganisms in water through strong oxidizing substances generated during the electrolysis process. During electrolysis, oxidation reactions mainly occur at the anode, generating active substances such as hypochlorite ions (ClO⁻) and hydroxyl radicals (·OH). These substances can penetrate the cell membranes of microorganisms, destroy their enzyme systems and genetic materials, thereby achieving a bactericidal effect.

- The cathode mainly precipitates hydrogen gas and hydroxide ions. This process can achieve precise control of the concentration of oxidizing substances by reasonably controlling parameters such as current density and voltage, so as to meet the treatment requirements under different water quality conditions. As a key breakthrough in this field, ion membrane electrolysis technology separates the anode chamber from the cathode chamber by setting a cation-selective permeable membrane in the electrolytic cell, allowing the strong oxidizing solution generated by the anode to be directly used for ballast water treatment, while the cathode products can be further used in collaborative treatment processes such as ship exhaust gas desulfurization. This structural design not only improves the utilization rate of chlorine, but also effectively avoids mutual interference between the reaction products of the anode and cathode.

The core of the electrolysis process lies in the control of the electrochemical reaction path. When ballast water passes through the electrolytic cell, driven by an applied voltage, chloride ions in the water undergo an oxidation reaction on the anode surface to generate hypochlorous acid, which further dissociates into hypochlorite ions. Meanwhile, hydroxyl radicals produced by the decomposition of water molecules under the action of an electric field have extremely strong oxidizing properties, which can react with macromolecules such as proteins and nucleic acids in microbial cells, leading to the destruction of cell structures.

When the effective chlorine concentration in the anode region reaches 5 mg/L, the kill rate of small typical organisms reaches 100%, indicating that this concentration threshold is a key parameter to ensure the treatment effect. Further parameter optimization shows that when the current density is in the range of 200-300 A/m² and the cell voltage is maintained at 24-36 V, the system can achieve high current efficiency while maintaining a stable generation rate of oxidizing substances.

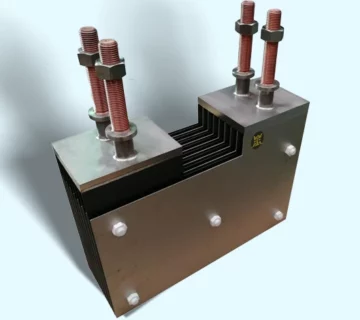

Titanium electrodes for electrolytic ballast water treatment

Titanium electrodes serve as the core material of the electrolytic ballast water treatment system,Its excellent physical and chemical properties directly determine the efficiency of electrolytic reactions and the stability of equipment operation. The titanium substrate itself is lightweight, has high strength, and good electrical conductivity. At the same time, a protective coating can be formed on its surface through various modification processes, which significantly improves its corrosion resistance.

Titanium electrodes can customize their electrochemical properties for different electrolytic environments through surface coatings, thereby meeting the multiple requirements of disinfection efficiency, energy consumption control, and equipment lifespan in ballast water treatment.

The electrode reaction kinetic characteristics of titanium electrodes are jointly determined by the intrinsic structure of the material, surface modification, electrolytic environment, and operating parameters. A deep understanding of the interaction mechanism of these factors can provide a theoretical basis for optimizing the energy efficiency and stability of the electrolytic ballast water treatment system.