Overview

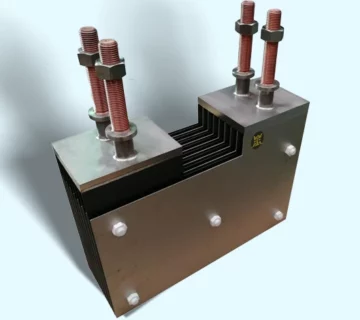

Mixed metal oxide coated titanium anode

Mixed metal oxide coated titanium anode, whose core structure takes titanium as the substrate and has one or more layers of mixed metal oxides coated on the surface.

The mixed metal oxide (MMO) coated titanium anode has a core structure with titanium as the substrate and one or more layers of mixed metal oxides coated on the surface. Common coated mixed metal oxides include oxides of ruthenium (Ru), iridium (Ir), platinum (Pt), etc. These mixed metal oxides have unique crystal structures and electronic properties, which are the key factors determining the anode performance. For example, the ruthenium – based oxide coating has good catalytic activity for the chlorine evolution reaction, which can reduce the over – potential of chlorine evolution and enable the reaction to proceed efficiently at a lower voltage. This is because the crystal structure of ruthenium oxide can provide abundant active sites, promoting the discharge reaction of chloride ions and accelerating the generation of chlorine gas. In the ion – exchange membrane electrolyzer of the chlor – alkali industry, on the surface of the ruthenium – iridium – plated titanium anode, the ruthenium oxide catalyzes the chloride ions in the saturated brine to lose electrons and generate chlorine gas, greatly improving the electrolysis efficiency.

The role of the coating is not only to provide catalytic activity, but also to enhance the stability and corrosion resistance of the anode. Although the titanium substrate itself has good corrosion resistance, it may still corrode in some specific electrochemical environments. The mixed metal oxide coating can form a dense protective film on the surface of the titanium substrate, preventing the electrolyte from coming into direct contact with the titanium substrate, thus protecting the titanium substrate from corrosion. The coating can also improve the electrical conductivity of the anode, making up for the insufficient electrical conductivity of titanium itself, ensuring uniform distribution of current on the electrode surface, and improving the efficiency and uniformity of the electrochemical reaction.

In different electrolyte systems, the electrochemical reaction processes in which the coated titanium anode participates vary. Taking the common chlor-alkali industry as an example, in the saturated brine electrolyte system, the main reaction occurring at the anode is the oxidation reaction of chloride ions to generate chlorine gas. The reaction formula is: 2Cl^- – 2e^- = Cl_2↑. On the surface of the ruthenium-iridium plated titanium anode, due to the catalytic effect of the coating, chloride ions can more easily lose electrons, thus reducing the overpotential of the reaction and increasing the reaction rate. At the same time, the dimensional stability and corrosion resistance of the titanium anode ensure that the electrode can work stably during the long-term electrolysis process, ensuring that the electrolysis operation is carried out under a stable cell voltage.

In the process of electrolyzing water to produce hydrogen and oxygen, if an acidic electrolyte is used, the oxygen evolution reaction occurs at the anode. Taking the sulfuric acid electrolyte as an example, the reaction formula is: 2H_2O – 4e^- = O_2↑ + 4H^+. In this case, the iridium-based coated titanium anode plays a role. Its coating can effectively catalyze the decomposition of water molecules, reduce the oxygen evolution overpotential, enable the reaction to proceed at a lower voltage, and improve the efficiency of water electrolysis. In an alkaline electrolyte, although the specific form of the reaction is different, the coated titanium anode can also promote the oxidation reaction of water to generate oxygen through its catalytic activity.

In the electroplating industry, such as in the chromium plating process, an electrolyte containing hexavalent chromium is used. At this time, the oxygen evolution reaction occurs on the surface of the iridium-plated titanium anode. The reaction formula is: 4OH^- – 4e^- = O_2↑ + 2H_2O (in an alkaline environment) or 2H_2O – 4e^- = O_2↑ + 4H^+ (in an acidic environment). The iridium oxide on the anode surface catalyzes the oxygen evolution reaction, and the electrical conductivity of the titanium substrate ensures uniform current distribution, enabling the chromium plating layer to be uniformly deposited on the cathode surface, improving the quality and performance of the chromium plating layer.

Iridium based oxide coatings perform outstandingly in the oxygen evolution reaction and are commonly used in electrochemical reaction systems where oxygen evolution at the anode is required. Iridium oxide coatings have high stability and catalytic activity, which can effectively reduce the oxygen evolution overpotential and increase the oxygen evolution reaction rate. During the process of water electrolysis for oxygen production in an acidic medium, the iridium-based coated titanium anode can efficiently catalyze the decomposition of water molecules to generate oxygen while maintaining good stability and being resistant to corrosion.

application

Principle of electrocatalytic oxidation for sewage treatment

In the process of electrocatalytic oxidation treatment of sewage, the mixed metal oxide coated titanium anode plays a crucial role.

Generation and Effects of Hydroxyl Radicals

In the process of electrocatalytic oxidation for sewage treatment, the mixed metal oxide coated titanium anode plays a crucial role. The electrochemical reactions occurring on its surface are an important way to generate hydroxyl radicals (·OH). When an electric current passes through the sewage system containing water and electrolyte, at the surface of the coated titanium anode, the water molecules will undergo an electrolysis reaction. The reaction equations are as follows: H₂O → H⁺ + OH⁻, OH⁻ – e⁻ → ·OH. The mixed metal oxide coating on the surface of the coated titanium anode, such as iridium-ruthenium oxide, has high catalytic activity and can accelerate this reaction process, promoting the massive generation of hydroxyl radicals.

Hydroxyl radicals have extremely strong oxidizing ability, with a redox potential as high as 2.8V, second only to fluorine gas. This enables them to react non – selectively with various organic pollutants in sewage. When treating sewage containing phenolic compounds, hydroxyl radicals can rapidly attack the benzene ring structure of phenolic molecules, triggering a series of oxidation reactions such as hydroxylation and ring – opening. In the specific reaction process, hydroxyl radicals first undergo an addition reaction with phenolic molecules to form a phenolic hydroxyl radical intermediate. Then, the intermediate is further oxidized, and the benzene ring undergoes a ring – opening reaction to generate small – molecule organic acids such as formic acid and acetic acid. These small – molecule organic acids are ultimately completely mineralized into carbon dioxide and water. When treating organic dyes in printing and dyeing wastewater, hydroxyl radicals can destroy the chromophoric groups of dye molecules, causing the dye molecules to lose their color and decomposing them into harmless small – molecule substances.

Removal mechanisms for different pollutants

For heavy metal ions, the coated titanium anode mainly achieves their removal through electrochemical reactions. During the electrocatalytic oxidation process, heavy metal ions undergo a reduction reaction at the cathode and are reduced to metallic elements or ions in lower valence states, thus precipitating from the sewage. Taking wastewater containing copper ions (Cu^{2+}) as an example, on the cathode surface, Cu^{2+} gains electrons and is reduced to metallic copper. The reaction equation is: Cu^{2+} + 2e^- → Cu. In the actual treatment process, when an electric current passes through the wastewater, copper ions migrate towards the cathode and gain electrons on the cathode surface to undergo a reduction reaction. The generated metallic copper deposits on the cathode surface, thus achieving the removal of copper ions. For some heavy metal ions with variable valence states, such as chromium (Cr), under acidic conditions, Cr^{6+} has strong oxidizing properties and is highly harmful to the environment. Through electrocatalytic oxidation, Cr^{6+} can gain electrons on the cathode surface and be reduced to Cr^{3+} with lower toxicity. The reaction equation is: Cr_2O_7^{2-} + 14H^+ + 6e^- → 2Cr^{3+} + 7H_2O. Subsequently, Cr^{3+} will form chromium hydroxide precipitate under alkaline conditions and be removed from the wastewater.

For organic substances, in addition to the oxidation by hydroxyl radicals, there are two mechanisms of direct oxidation and indirect oxidation. Direct oxidation refers to the direct loss of electrons by organic molecule on the anode surface and being oxidized. For example, ethanol (C₂H₅OH) can be directly oxidized to acetic acid (CH₃COOH) on the anode surface, and the reaction formula is: C₂H₅OH + H₂O – 4e⁻ → CH₃COOH + 4H⁺. Indirect oxidation utilizes other strongly oxidizing substances generated by electrochemical reactions, such as hypochlorous acid (HClO), persulfate (S₂O₈²⁻), etc., to oxidize organic substances. In sewage containing chloride ions, chloride ions are oxidized to chlorine gas (Cl₂) at the anode, and chlorine gas reacts with water to form hypochlorous acid. The reaction formulas are: 2Cl⁻ – 2e⁻ → Cl₂, Cl₂ + H₂O → HClO + H⁺ + Cl⁻. Hypochlorous acid has strong oxidizing properties and can oxidize the organic substances in sewage. When treating wastewater containing petroleum pollutants, hypochlorous acid can oxidize and decompose the long-chain hydrocarbon molecules in petroleum substances into small-molecule fatty acids and alcohols, further reducing their harm to the environment.